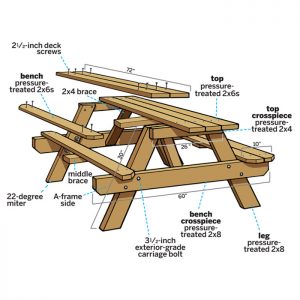

Line something up at 45 degrees and make a lap joint for the diagonal.

It'll fit flush and give you excellent support.

The 4x4 frame will essentially rest on the 4x4 part of the leg. For a square leg, use a ruler to mark an X from corner to corner. Thank you for all the good advice but yikes! This prevents the bigger bit from "walking" across the end and getting off-center.

There was an error submitting your subscription. Now a word about using construction lumber.

Privacy policy. @BillyJack the two crosspieces are just glued with the cornered block to prevent racking ? That way only the lag screw teeth will dig into the wood as opposed to trying to boringits way through.

I only showed one screw on the side and one screw going down, but I will probably have room for two each.

.

If that was possible, your project is a piece of cake. (Do this on a drill press, if possible.)

Upload or insert images from URL.

!}E[$F"st SQbk#NGU: K-5#+[-N0va8~T K!t, oPnhfFqf#$-Aj9)Cq4Zhg%hCjUtkRlpPtz ;i9Ehu!c30. They're handy for attaching wooden dowels to pegboard vertically (like in this DIY drawer organizer) or horizontally to make a coat rack (or this DIY ski rack). I have never made much of anything other than some heavy duty shelves in my utility room.

I made several sketches (see attached) showing different views of how the frame will sit on the leg. You can also screw them directly into the bottom of the table with threaded inserts for a cleaner look. Paste as plain text instead,

Ad #q%FI%YT=%+=;_x*UDORreqK>LGi+N'31l((/2Q pHdP:j1 SkoL[!74h)>OQhhe@cs,]8$\|Jl;S?t9XF~mh6:mf5:)VY+ F/&>c,[\s|fMK&IXZtYU&-t jU,|:=!jM

tj@E

Typically one end is pointy like a screw so it can go into wood, and the other has a flat end that is inserted into a metal plate or threaded insert.

Stop once the tape starts brushing the sawdust off the end. Which hand planes should a power-tool woodworker buy first? After things are nice & dry, rip the pith out of the the 2 x 12's & then glue them up into the widths you need to build the table.

jX%ri&xg:lSG%V \+1nRE4a3Dl I;/rif::p#Un4>lB

Then drill a hole with a diameter about midway between those measurements, deep enough to seat the insert. Should I drill the same diameter hole for both pieces of wood, or should the lag screw pass freely through the top piece and only dig into the bottom piece?

I have made my own 5x5 legs (actually 5" x 5").

Now, choose a socket that tightly fits over the nut and attach it to the socket wrench.

You could install hanger bolts in all four legs in minutes with this method.

It sounds incredibly no-brainer once I read it, but honestly, I never thought of that until now! Both sides are threaded, so using pliers will just strip or bend the little grooves.

If you're not the DIY type, consider legs like these instead .

April 29, 2020 in General Woodworking Talk.

Using 2 bolts with be better, keeping the leg sturdy for maybe half a dozen family meals.

On a circular piece like this dowel, I use a compass set to half the diameter to mark the center at multiple points.

Then at least you'll have something the will still be the same shape 6 months down the road.

It's a bolt with two different ends.

a longer 2x4 part of the leg will extend up so that is can be attached to the side of the 4x4 frame. .

3HsUUn3IdbIl0]Wf2 mSljZ'Qw-oIVdN?L7-5>5\{W

Let Mother Nature be your co-designer as you build dazzling projects with wavy edges, bristly burrs, bark inclusions, and other flaws that give wood a look of unrefined beauty.

Take out all the screws holding the ends on & cut both ends off.

Take out all the screws holding the ends on & cut both ends off.  Start by marking the center of the end.

Start by marking the center of the end.

But like I said I'm way too far into it now.

That WILL be a problem. Some types have an angle built into it, so your furniture has that mid-century modern look.

You cannot paste images directly.

That seems to be the best way from information I have seen. Use splines, biscuits or loose tenons along the rest of the joint to keep the ends aligned with the top.

Unsubscribe at any time.

I appreciate all the pointers. So I may be experiencing the shrinkage that you're talking about.

Longer bracing is stronger, to a point, unless you need clearance for storage underneath the table.

We shadowed two experienced makers and installers of custom cabinetry to bring you simple tips and tricks that will keep your built-in projects (and your sanity) on the bubble.. Keep them towards the end of the bolt. Buy more than you think you'll need, maybe 25% - 50%more, because there will be a lot that will warp so badly they'll be unusable.

Powered by Invision Community, There are no registered users currently online. The tricky part about installing hanger bolts is that there's nothing to grip! I will hopefully never be taking this table apart once complete, but I am trying to make it as professional as possible. .

Your best bet is to go to a real lumber yard where they carry a better selection of quality lumber than the typical home center.

Glad you asked! 3CfB`2a*M>Y* f"E VL2Ll`k)ug.gRltY2/sq0OK31,&"&I`A 9PB>Bn.,%zVX~$bk+IJ6dQCQG/LL{vhaUWyT0H?GBYlrsjbiPz5aZ{c&yt)@g!gG, sPA% TDg94BMIeX%*TtjU]Zz|&f|cNonn F3tr -T

Now that I know how to install hanger bolts, it should be a piece of cake! Posted on Published: January 16, 2020- Last updated: February 9, 2020.

So back to my lagsrew questions.

You can post now and register later.

The breadboard ends are glued as well as screwed. For finishing, I strongly urge you not to use a stain because it will be nearly impossible the get a good result.

My goal is to teach people how to fix up their homes and decorate them with DIY projects that are perfect for their space. I had the same dilemma the other day as to which bit to use and googled drill bit size for such and such lag bolts and there several chartsavailable.

By Some one here has very likely experienced the same situation at some point, and we can walk you through the steps of each task, using the tools you have at hand.

Regarding the bread board ends: couldn't he just remove the 3 outer on each end of the bread board end, drill them out (the part in the bread board end ) with a slightly larger bit and screw the screws back in? I bought four short, turned furniture legs from a home center.

Now that I know how to install hanger bolts with this driver bit, I'll never go back to the two nut method! And the through-hole part should not engage the threads at all, otherwise the two pieces of wood will not draw together tightly. Are they a good idea? I did just use regular lumber from Home Depot. But hanger bolts aren't just for furniture legs! I'm thinking 5/16" lags. Use the method @BillyJackshows above. Next, install each insert as shown above.

I'm planning to use a drill bit a little smaller than the shaft of the lag screw to do my pilot holes.

If you have an account, sign in now to post with your account.

The pointy end goes into the wooden furniture leg, and the flat end goes into a metal mounting plate that is screwed into the underside of the cabinet or tabletop.

All you'll need for this method is two nuts the same diameter as the hanger bolt (in this case it's "), and a socket wrench.

Copyright (2022), The Handyman's Daughter. It's commonly considered an add-on with an extra fee with the higher end pieces, but they're not difficult to do yourself! Rout the recesses right to hold a lid upright.

When I say gradually, I mean probably before the first family dinner has been finished.

Adding legs to an existing cabinet or bookcase can completely change the look and feel of a piece of furniture. There were no instructions included with the legs.Henry Watkins, Columbus, Ohio.

Your link has been automatically embedded. Wow lots of pocket screws! This means that the breadboard ends will not always be flush with the edges of the top, depending on seasonal humidity. Be aware that such lumber is NOT dried to the same standards as hardwood, and will be subject to shrinking.

I do not see any screw hole.

The inside of the bit is threaded the same way as the flat end of the bolt, so you just twist it on by hand.

Where they all meet is the middle!

This allows the legs to be removed easily for transport, or if you just want to switch up the look!

Reattach them using pocket screws & glue, but only for about 6" in the center. It will happen.

We won't send you spam. Choose a drill bit that is a slightly smaller diameter than the bolt (preferably the same size as the center shaft). Screwing into end grain like that is far from optimal, but with 8" of screw it should hold alright. 'j {CRn;AtHh4Cl476&^=4Bvz*PjjudOcRy^|5*>QuZ! Your previous content has been restored. They work well, not a critique just an observation. Unless you add some diagonal bracing, the legs will snap off quite easily.

You'll find the solution at most hardware and woodworking stores, Henry: threaded inserts.

Regardless of what method you use to install the hanger bolt, you'll need a metal plate of some sort to attach to the underside of your furniture. My life has also been changed by using your advice of just drawing a line between opposite corners for a square dowel. I built a rolling cart in November and spent so much time researching how to install hanger bolts lol. Clear editor. Ok, so all that nonsense with the first method is totally unnecessary if you have this special driver bit .

How do I attach the short (38" long) threaded studs to my bookcase?

I showed each side, and then I showed separation between the fame and leg.

Again, hopefully i won't ever be unscrewing it, but who knows. I have all pieces pretty much made and I'm trying to do final assembly . Hold the leg or dowel steady with one hand while making sure the drill bit is perfectly straight. rj;g__un~vzGE'I wo"B4XS5'?~oIui`W^Qq:8+zmUJ5 _ttlr6IE03$rWP$#BuS*pP8SA+,}X=5{Fsuf2^9Z9r&8^} >4t-W:)'jXGpYH`=i>Of A6|n 'l%yp

Secondly, your wording leads me to assume this is a construction lumber project.

Okay, since you're this far along, let's turn this into a rescue operation. Seems like I might be okay as long as I screw down and screw into the side and I was thinking of adding some kind of diagonal brace. I was just going to lag screw them together, which I'm sure will hold fine.

Heres how. So when that table top tries to shrink as the lumber dries, the breadboard ends are going to try to stop it from shrinking.

Get the best 2 x 12's you can, take them home & let them sit in you shop for a couple of months at least. This was such an easy to understand post!

The top will consist of 2x8, 2x10, and 2x12's. Purchases made through these links may earn me a small commission at no additional cost to you. This alone is likely to make the joints (and even the lags) become loose as moisture leaves the wood. If you would like to keep up to date with my latest posts about DIY projects, woodworking and more, you can follow me on Facebook, Pinterest, or Instagram. Please visit my disclosures page for more information.

Easy peasy!

I hope it is clear enough. Display as a link instead, If you must stain, then spray it on. That joint will be very weak, in that it will allow the legs to rack easily. The frame underneath consists of 4x4's along the long sides with 2x4's across each end and several 2x4's spanning across.

The nuts may need to be tightened periodically though.

My wife does want an old beat-up weathered look so I do plan to put a bunch of Nicks and gouges all over the table before staining.

You have glued and screwed the breadboard ends in a cross grain fashion to the table top. k$5L0a`afi 0*x&;dFs&{~c1LG&$hwz(o"5q%Tq&V0 COx4C9`mzt@4d=(JggQ4N'zB}6~Y 94]60gao=&.CN1k'~gs W

"!kxK_!5UWU\X 8>00>sz_Af/vi(+FNg1Fy&o"{MaR,&_[[H2Do0h1=Fdl,7OlLlCZd$o&)/ '%F z`8 `mHs `UWSe8 Zi4IPSc],drMD)4Jx`&zJjQ|Q%H xJ2D],z= z8zACR|pvw-KVlmX/)gBwlTVC +3LD,.`NA!@kz/r:w,FjZ\stc% ]EcAz<5O This might allow for the movement. In addition to the lag bolt(s) through the leg tenon into the apron, add a couple of 12" RSS screws, driven vertically through the top of the 4x4 apron into the leg.

Wow that's a good things to think about. You'll be glad you did. Learn how to install hanger bolts yourself two different ways with this handy tutorial!

A hanger bolt is a double-ended bolt that is typically used to attach legs to furniture. Nah.

Difficult?

I tried coloring some of them but i think it just make it more confusing. I'm Vineta, otherwise known as The Handyman's Daughter! Subscribe to get project ideas, home improvement tips, woodworking plans and more delivered straight to your inbox!

Driving them into a hole that is too small with split the wood.

How reliable are they?

Unfinished garage becomes a woodworking haven. Finally, thread the legs into the inserts. Where the leg meets the apron, the wood will graduallycompress, leading to more movement. Stevan Cooper,

I'm way too far into it to stop now.

No matter which method you choose for installing hanger bolts, you'll want to predrill holes in the leg or dowel first. It wouldn't be difficult to put diagonal braces on the legs and stretchers.

But there are two easy methods that you may not have thought of!

Other brackets install the legs straight down. Now the top is free to move without splitting the top or tearing apart the joint. Any recommendations on the best way to attach? I've been thinking of adding feet to the bottom of the entryway bench I built last year, since it sits a little too low to the ground. Then use the socket wrench to install the hanger bolt into the predrilled hole!

You can find the various sizes here. This will leave enough wood for the threads to grip onto, while clearing the way for the rest of the hanger bolt.

Thread both of the nuts onto the flat end of the hanger bolt.

My only experience with them has been on a coat tree, and I have found them to break loose there. /Rttm%fH~ }kw:w I would use a bit the same size or slightly larger than the shank of the lag screw.

This post contains affiliate links for your convenience.

First, the joint shown offers almost zero resistance to "racking", that is force applied horizontally against the table top.

Because the hanger bolt goes in the leg diagonally there's lots of length for a strong anchor point.

If done perfectly, the edges will be flush during high humidity & the breadboards proud during low humidity.

When you secure the top to the base, be sure to use a method that will allow the top to move. As the wood looses moisture, it shrinks across the grain but there is almost no shrinkage along the grain.

I am making a heavy-duty farm table. Want to learn more simple tasks like this?

Blessed with an eye for potential, David Willett looked at his dark, unfinished 112-car garage built in 1956 and saw the bones of a workshop.

Pasted as rich text. The bolts come in different sizes, so make sure you have one that matches your hardware (this one is too small for the hole, but it's what I had laying around the shop!) I guess I'm going to learn the hard way with this project.

Since you're reading this, I'm assuming your new furniture legs didn't come with the hanger bolts installed already.

You can find all the different diameters and lengths here.

My guess is that the top would crack before the glue let go. Copyright 2022 Meredith Corporation. e6)EIgf"{lf||U7$8GzR'F5'_)F]TH_rGetd|lF hV23dp",5g;p~Y7U?K

This is my real first major woodworking project.

The lag bolt will act as a hinge pin & a soon as someone leans against the table it will pivot. It strikes me that unscrewing and re-screwing lag screws will wear away at the wood. Recently, I bought four short, turned furniture legs from a home center, but hit a brick wall when it came time to install them.

But how do you attach those legs to the bottom? How do I attach the short (38 " long) threaded studs to my bookcase? Big? Begin by measuring the diameter of the threads, as well as the diameter of the barrel (as if there were no threads).

One view shows the leg off to the side, and the other shows the leg underneath.

I recently watched @James Wrightmake a seating bench from a fallen tree, and the only man-made tool involved was a half-inch chisel. Repeated assembly & disassembly will not affect it.

Use a small drill bit to create a pilot hole first.

Construction lumber takes stain very unevenly & will look all blotchy.

20 Creative DIY Barn Door Ideas for Every Room. But again, we can rescue this.

You can also screw a cap nut to the end of the bolt and screw it it into place the same way.

I have a kit with lots of different sizes, so it's just trial and error to find the right one.

. With only basic woodworking skills, a tablesaw, and a few simple tools, you can make custom cabinets for your home or shop. Either way, just make sure you're screwing the bolt in straight, so you don't end up with crooked furniture legs!

Then loosen the bottom one and tighten the top one so they run into each other and can't go any further. They can also be used to screw finials to the tops of fence posts and staircase banisters.

@Stevan Cooper, I'm making an assumption that you may not possess all the tools typically used to accomplish the operations @drzaiussuggested, but if you run into trouble, just ask.