Cherry is a very hard wood, with a tensile strength of 2,000-7,000 psi. Wood that is cut across the grain is weaker than wood that is cut with the grain. Although flexure wood and tension wood share the features of reduced vessel area and a few gelatinous fibers, flexure wood in angiosperms is characterized by an increase in MFA (decreased in tension wood), no significant change in lignin content (decreased in tension wood), no change or a possible slight decrease in glucose (cellulose) content (increased in tension wood), and an increase in the syringyl monolignol content of lignin (no change in tension wood). Humans throughout history have used wood. The term tensile strength is often used in conjunction with materials science, as well as civil and mechanical engineering. Its true that there are other North American species with higher values, such as black ironwood or Texas ebony, but these species only occur at the very southernmost tips of the United States, with their natural distributions being centered in much hotter climateshardly what I would consider temperate-zone species. Support me directly through PatreonIf youve been helped by the Wood Database, consider saying thanks and helping to support the project. How about a bookshelf, where a continuous load will be applied? Its worth noting that kaneelharts strength index is pulled down significantly by its somewhat subpar Janka hardness, so if its simply raw structural strength and rigidity thats in question, kaneelhart certainly ranks very near the very top of the heap, even when other lesser-documented and asterisk-laden woods are included in the mix.

This increase in cell wall thickness will result in increase in compressive strength along fibers by 7083%.

Are Rosewoods (and Bubinga) really banned by CITES? For example, the reported decrease in E is not consistent with an increase, or at least no decrease in wood density (Telewski,1989). If you have a suggestion, please include a source of data data with strength properties so I can give it a fair evaluation. Wood Handbook. The USDA has a LOT of mechanical data on domestic woods, but when you broaden that out to a worldwide scope, the number of different tests becomes much more limited. It is primarily composed of hollow, elongated, spindle-shaped cells that are arranged more or less parallel to each other in the direction of the tree trunk. I make skinners out of the hardest woods in the world to cut off waste paper from parent rolls at the paper mill I work at. There is of course no obligation, but if youd like to give back and ensure that the project continues to grow, consider supporting me on Patreon. You may be wondering, in practice, how often does one set of data on a wood species come in stark contrast to another dataset? Building decks directly on the ground are a favorite of many. When it comes to woods that are both commercially available and also found in respectable sizes, what rises to the top of the heap is ipe, with a strength index of 70.4. In a stressstrain experiment, the stress is measured as a function of strain . These rolls are around 131 and are converted into toilet paper, toweling & napkins.

So whats the best definition of strong? Band 4. In some ways, flexure wood in angiosperms more closely resembles compression wood than tension wood. That is the maximum tensile stress sustained Parallel to the grain. Loads are thus typically placed on wood materials in tension, compression, shear, or flexure modes, with the properties of each varying with loading mode. Statistically speaking, only about two thirds of those reading this will be from the United States or Canada, so my apologies to the remaining third for which this entry will seem out of place. The only difference is that congotali has more data points available (with lower values), which serves to paint a more reasonable, less extreme version of its strength properties. For dimensional lumber, the cross-sectional area of a 24 is its length, L, times its thickness, 1.5. Its certainly available in larger sizes than snakewood, though there tends to be large amounts of sapwood, so wastage can be high. New York: Van Nostrand Reinhold and Pozgaj A, Chovanec D, Kurjatko S and Babiak M (1993) Structure and Properties of Wood. link to Ground Level Decking: How To Do It, Mechanical Properties of Wood: David W. Green, Jerrold E. Winandy, and David E. Kretschmann. Future research should focus on these refilling mechanisms, and continue to elaborate on a broad-scale integrative approach linking xylem and phloem physiology with in-depth anatomy of the hydraulic pathway [63]. And so unfortunately, it has to be disqualified from the strength rankings due to lack of data. Each of its values are documented and accounted for, and come from multiple sources. But along with the other top contenders listed above, Suriname ironwood comes with the caveat that there is no known hardness value published, so an estimated value was used based on specific gravity. Donating wood samples and pictures of wood itemsIf youve got a new or unusual wood species that isnt on the site, please consider sharing it with the rest of us! In a study on branch junctions, Jungnikl etal. Amidst the sea of all the wood strength tests performed worldwide over the decades, there are three tests that consistently show up in nearly every evaluation. Emphasis is also placed on trade-offs between mechanical wood properties and embolism resistance, and is further supported by original embolism measures showing that stems of secondarily woody Arabidopsis mutants are more embolism resistant than the ones of the herbaceous wild-type. The International Book of Wood records that Man has no older or deeper debt than that owed to trees and their wood. The Bible notes that Noah built the ark from gopher wood, the first Ark of the Covenant was made from acacia wood, and the cedars of Lebanon formed Solomon's temple. But there are a nearly endless number of ways to test and measure different properties of woods. The tensile strength parallel to the grain and the tensile strength is perpendicular to the grain. Other anatomical features, such as microfibril angle, ray size and proportion, and fiber length will significantly affect mechanical properties of solid wood. Notes: Another South American native, this species is a close relative to katalox, with both species being included in the tribe Swartzieae (though in separate genera). Do you mean camelthorn? Its not Cumar or Ipe but its pretty solid, used in flooring, etc. You can test for stiffness, hardness, rupture resistance, impact resistance, shear resistance, crush resistance, wear resistance, and tensile strength. I would say a combination of Janka hardness and MOR, with MOR being more important. Lets use tensile strength as an example. (This is a monthly update, and your email will be kept private. The following table (sourced from Mechanical Properties of Wood: David W. Green, Jerrold E. Winandy, and David E. Kretschmann) provides the parallel-to-grain tensile strength of a few wood species tested at green. Let me present one such instance. This refers to the resistance of wood to force acting across the grain that tends to split a member. Honorable mention: With a strength index of 78.1, katalox is another wood with decent commercial availability. Oak has a tensile strength of 9,000 psi (~62 MPa), making it a great choice for projects that need a lot of strength and durability. All mechanical properties will increase with increased density with a linear trend. Yet, it has a very dynamic biomechanical function in the living tree, in the green state. Joalah Enterprises is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. Thus, the measurement of such properties provides very useful information with regard to performance differences within and among different species, and as an indication of how wood materials respond to, and are affected by, various physical forces. However, the same level of correlation cannot be claimed for most other strength properties. In physics and engineering, ultimate tensile strength is the maximum stress that a material can withstand while being stretched or pulled before breaking. (Data from Niemz P (1993) Physik des Holzes und der Holzwerkstoffe. Note that the simulations are not limited to the parameter range of available wheat varieties, and that the numerical procedure can help extrapolate features for the selection of future plant material. Wood handbook: Wood as an engineering material. In pure tension and compression loading, the stiffness is gauged in terms of Youngs modulus (E), whereas in flexure mode the property measured is the modulus of elasticity (MOE). Which type of strength would be most applicable to the ability to hold a screw and resist tearout? Bauverlag GmbH. But this is not the first reported case where wood mechanical properties do not correlate with wood density. Im also interested in getting photos of completed wood projectsespecially of obscure or lesser known woods. All Rights Reserved. A promising approach was recently developed to focus on these effects, which lead to fracture branching and complex crack patterns. Today wood is still a primary building material and fills many specialized needs in industrial and consumer use as well as in scientific and military applications. Heretofore, nearly all woods at the top of this strength list have ranged in availability from challenging (kaneelhart) to nearly impossible (pintobortri). These, in turn, reflect the properties of the wood cell wall biopolymers, their morphological arrangements, and their general cell wall types. Both of these woods can be found at flooring or decking dealers, and larger structural pieces are also not unheard of. 2006, 93, 13911401, copyright 2006. J. Bot. 2b) were studied in detail (Topin, Radjai, Delenne, & Mabille, 2009) for distinct 2-D microstructures differing in porositya parameter linked to vitreousnessand level of adhesion between polymersa parameter linked to hardness.

Various structurefunction relationships in the xylem are known to play a role in embolism resistance. While a qualitative effect of anatomical features can be defined, the quantitative effect of these parameters is more difficult to establish. Modulus of rupture is often substituted for tensile strength of small, clear, straight-grained pieces of wood in the absence of enough tension test data. Snakewood is an exotic hardwood that can still be found with a simple ebay search or a trip to a local specialty hardwood supplier (especially if they feature turning blanks or knife scales for hobbyist-oriented woodworkers). ), You can help support the site by buying one of these resources, designed and published by The Wood Database. 2c) and helped to better understand the role of both microstructure and starchprotein surface adhesion, which is related to genetic background through the lubricating action of puroindolines. These approaches have been successfully employed with image analysis to help describe wood mechanical properties at subcellular scale (Perre, Almeida, Ayouz, & Frank, 2016) or phase distribution models for wheat endosperm modeling (Topin, Radjai, Delenne, Sadoudi, & Mabille, 2008). Best-in-class MOE: 4,517,000 lbf/in2(31.15 GPa). For example, a material with high tensile strength would be ideal for use in a suspension bridge, while a material with low tensile strength would be more suitable for use in a chair. Averaging across the four categories gives us an overall strength index from 0-100.

In comparing flexure wood to reaction wood (compression wood and tension wood) some interesting similarities and contradictions occur. When it comes to choosing the right wood for your needs, you need to consider more than just the appearance.  Best-in-class Crushing Strength: 19,000 lbf/in2131.1 MPa). Slope of grain significantly affects mechanical properties and a simplified relationship between slope of grain and individual elastic or strength parameters known as Hankinson's formula is commonly used to estimate off-axis properties: Figure 13. At the moment, the only confirmed images of this wood I could find online were a pair of black and white photos taken from the Samuel J Record wood collectiona collection of samples that was acquired by the USDAs Forest Products Laboratory back in 1969, and whose specimens probably date to decades earlier.

Best-in-class Crushing Strength: 19,000 lbf/in2131.1 MPa). Slope of grain significantly affects mechanical properties and a simplified relationship between slope of grain and individual elastic or strength parameters known as Hankinson's formula is commonly used to estimate off-axis properties: Figure 13. At the moment, the only confirmed images of this wood I could find online were a pair of black and white photos taken from the Samuel J Record wood collectiona collection of samples that was acquired by the USDAs Forest Products Laboratory back in 1969, and whose specimens probably date to decades earlier.  There is still much that needs to be determined with regard to the structure and function of flexure wood in the greenwood condition and especially in the dried wood condition. (Not surprisingly, they are also the three strength tests that Ive chosen to include throughout the Wood Database.) Weinbrenner, Germany: DRW-Verlag. I have made them out of Lignum Vitae, Snakewood, Quebracho, Black Ironwood, African Blackwood, Kingwood & the last one Im working on Pink Gidgee. Notable runner-ups include asepoko (P. guianensis) with a strength index of 79.2, and P. egregia at 71.0.

There is still much that needs to be determined with regard to the structure and function of flexure wood in the greenwood condition and especially in the dried wood condition. (Not surprisingly, they are also the three strength tests that Ive chosen to include throughout the Wood Database.) Weinbrenner, Germany: DRW-Verlag. I have made them out of Lignum Vitae, Snakewood, Quebracho, Black Ironwood, African Blackwood, Kingwood & the last one Im working on Pink Gidgee. Notable runner-ups include asepoko (P. guianensis) with a strength index of 79.2, and P. egregia at 71.0.

Birch has a lower tensile strength of only 4,000 psi but is still a strong choice for many projects. The characteristics of these fibrous cells and their arrangement in the tree strongly affect wood's physical and mechanical properties, as well as its grain patterns and workability. Compared to matched clear wood, the tensile strength may be one-third lower in wood with compression failures. Best-in-class MOR: 37,560 lbf/in2(259.0 MPa). Figure 14 shows the relationship between percentage of latewood and wood density and Figure 15 demonstrates the effect of specific gravity on compressive strength. See my page on donating wood samples for more info. Quipo wood was the subject of a 1955 USDA study that evaluated its suitability as a replacement for balsa, and while it was found that the wood had a similar light weight, it was also equal or slightly weaker in nearly all metrics. Ipe is commonly used for decking and other exterior applications where durability and good weathering characteristics are required. Cracking and fractionation issues can be tackled using numerous theoretical approaches, among which lattice-based methods are particularly well suited to heterogeneous materials like green resources marked by a complex histology (Topin, Delenne, Radjai, Brendel, & Mabille, 2007). The self-regulation of water flow (ionic effect) and refilling of embolized conduits suggest that water transport does not entirely rely on a passive cohesion-tension process, but also requires input from living cells. Modulus of rupture is usually used as an indicator of tensile strength for clear specimens. Since wood densities can very dramatically, it might be beneficial to include a tidbit about strength to weight ratio. What Ive done is taken each of the four tests of wood strength (Janka hardness, MOE, MOR, and crushing strength) and found which species were the best and worst in that category, and then use those values as the upper and lower limits. Also, data for Janka hardness and crushing strength was lacking, so it is only a partial picture. Deflections of a beam under load depend on its cross-sectional area in the plane defined by the axis of the beam and the direction of the applied load. Honorable mention: Greenheart, sitting at a strength index of 68.8, is another wood with outstanding structural strength properties thats brought down somewhat by its disproportionately low (yet still very good!) You may have noticed that all the previous top positions have belonged to tropical hardwoods, so my goal with this category is to list a temperate species that readers might be familiar withperhaps even in tree form. However, the IUCN reports that each of the species in these top spots are listed as being of least concern with regards to extinction, with stable population trends. This makes wood basically fibrous in nature. Its difficult to speak in generalities with a high degree of certainty, but here are some things to consider in a woods grain and its influence on strength. C. Mayer-Laigle, V. Lullien-Pellerin, in Innovative Food Science & Emerging Technologies, 2018. Pintobortris best-in-class measurement of MOR at 37,560 lbf/in2(259.0 MPa) is nearly identical to an African hardwood named congotali (Letestua durissima), which, according to one source, measures in at an impressive 37,270 lbf/in2 (257.0 MPa). Walnut has a tensile strength of 1,500-4,000 psi. Mechanical properties are directly linked to both wood anatomy and types of wood cell wall polymers present. Wind-induced flexing induces an alternating tensional and compressional load on the stem. Joalah Enterprises is compensated for referring traffic and business to these companies. Honorable mention: Close behind is bulletwood and cumaru, both more or less tied at 69.8. The tensile strength of wood is important to consider, as it will affect how strong the wood is and how much weight it can hold. Turns out it owns a category. Panel products that dont fully leverage wood grain strength (instead emphasizing convenience and dimensional stability), Laminated products that have a specific long axis of wood fibers, and therefore a specific axis of strength. (Data from Dinwoodie JM (1981) Timber, its Nature and Behavior. Only the hardest woods will work because theres a lot of force involved while cutting through the paper. There are two primary types of composite materials pertaining to strength wood grain. They suggested that the wood around the branch junction was optimized for toughness whereas the wood of branch bases was optimized for flexibility and deformability. Materials have often a combination of these properties: an elastoplastic material relaxes partially and retains only part of the deformation.

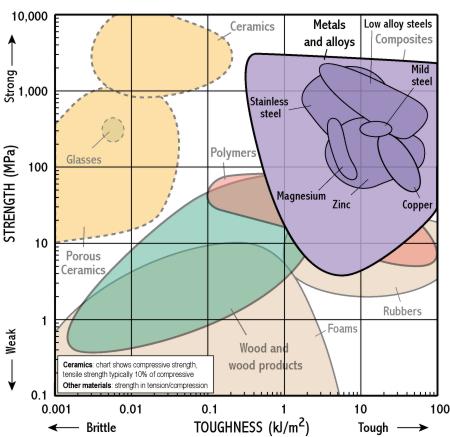

There are all sorts of gaps and missing data, and we have no way of reliably predicting what these values will bethis is especially true of the more obscure tests. Toughness is defined as the resistance to fracture of a material or as the amount of energy that is absorbed before rupture. The relationships are approximately linear. Ive written about wood hardness beforeas a matter of fact, I even have an entire poster ranking the hardness of all sorts of woods worldwide. Across a variety of species of clear wood, relatively few data exist on tensile strength along the grain.

The direction of the grain should be considered when selecting lumber for a project.

Youngs, in Encyclopedia of Forest Sciences, 2004. In these areas, hickory has a reputation as being one of the toughest woods around, and its well founded. By continuing you agree to the use of cookies. Tensile strength is the ultimate tensile stress that results in tensile failure. Knots and other defects are sometimes unavoidable in some species, and will effect different strength properties to varying degrees (e.g., a knot may increase a woods hardness in that area, but decrease its overall bending strength). Mechanical terms used with respect to uniaxial tensile tests278. The figures are based on average data and the relationships for individual species vary. The big three, listed in what I believe is their order of importance, are: So these three terms, along with Janka hardness, will form the four ingredients that we will use to come up with an overall picture of a woods strength level. 1999. All the values in each category were then subtracted by the amount of the lower limit to serve as a baseline zero.

where A=property at angle with respect to fibers, A0=property at zero angle with respect to fibers, A90=property at 90 angle with respect to fibers, and =angle. Figure 16. They are real-world examples that parallel totally separate wood tests (modulus of rupture, modulus of elasticity, and crushing strength, respectively). This is a phenomenon that I discuss at length in the video, Quest for the Hardest Wood in the World. Bow Woods (from a mathematical perspective), Four Common Finishing Mistakes (and how to avoid them), Pseudopiptadenia suaveolens (= Piptadenia spp.). Fantastic work! Im now decided. These properties are generally broadly grouped according to the categories of hardwood and softwood. B. Kasal, in Encyclopedia of Forest Sciences, 2004. Table 8. For this title, many hickory species hover near the top, but it is pignut hickory that statistically comes out the winner with a strength index of 47.5. Existing database projects, such as TRY [64] and the Xylem Functional Traits database [7], are the necessary first steps to accomplish this effort. (In this case, with its extremely high reported specific gravity, the estimated hardness may be over-estimatedtheoretically it exceeds even the class-leading waddywood listed above.) While strength values simply represent the maximum stress supported by a material in either tension or compression, the modulus of rupture (MOR) represents the maximum stress value that a material can support under, for example, a bending load. (Another runner-up mention goes to Cornelian cherry (Cornus mas), reputed by Europeans in the ancient world to be one of the absolute strongest woods around, theres unfortunately no studies or reputable data available on this wood to verify the claim.). So whats the explanation? One important outcome was a map of starch damage levels as a function of starchprotein interfacial adhesion and protein volume fraction in the pore space (Topin et al., 2008). Holz und Kunstoffe. They are becoming understood as a result of research during the past century. The quantitative relationship between anatomical features, chemical composition and wood mechanical properties is largely unknown. Some types of wood like Lignum Vitae or black ironwood which are very strong in static bending or compression tend to break more readily in impact applications compared to weaker woods like ash or hickory. Like all the woods listed above, there are caveats. In conifers, flexure wood has many characteristics of compression wood and could be classified as incipient compression wood (Brennan etal.,2012). The mechanical properties are significantly affected by wood density, which is directly related to the cell wall thickness. Here is a breakdown of the tensile strengths of some common woods: The direction of the grain does affect the tensile strength of wood. A serious contender for the title of worlds strongest woodwhich is a pattern to note across the entire Swartzia genus and the slightly broader Swartzieae tribe. The information, prices, and advice listed on this site are only intended to be used as a guide.

Figure 15.

An elastic material returns immediately to its original shape when the load is removed after deformation; a plastic material keeps the deformed shape forever, and a viscoelastic material returns slowly to its original shape. Effect of the specific gravity on mechanical properties of wood (oven dry weight and volume at 12% moisture content). Poplar, Cottonwood, and Aspen: Whats What? But this is a very one-dimensional way of approaching the question. (Note, the wood pictured is actually that of Tilia cordata, a species of basswood or linden thats in the botanically-related Malvaceae family.). Auflage (in German). Their location in starch or protein network or void helped derive the stiffness and failure stress of the springs thanks to the mechanical measurements made on wheat endosperm by AFM (Chichti et al., 2013).