Wall and Ceiling Repair Simplified: 11 Clever Tricks. You are correct. 3. can foam panels be directly glued or screwed to roof deck (being careful not to penetrate 1.5 thick t&g deck which is the interior ceiling and or hit rafter beams on 48 spacing? You barely hand nail them to keep them in place. This is for a gazebo. Its an expensive nail. But each piece needs to be completed as you go from side to side, hip rafter to hip rafter before you move up to the next piece. Another thought/question - I have a large portion of my roof that is over an upstairs porch - so ceiing boards of the porch are the roof deck - but other than making sure the new added foam comes past the exterior wall - I don't need to waste all that money on foam panels placed above the exterior open porch below - can i just 'shim out' to match depth/thickness of whatever I do on the roof over the interior house - so it comes flush with that?

What was your perfect sandwich combo. They are not a homeowner place, have your things figure out rather than expecting them to answer questions

In fact, T&G boards are most frequently used when the sheathing is visible from the inside such as in cathedral ceilings or in some cabin-style homes, especially if the span of the rafters is greater than 2 feet. First you need a solid air and vapor barrier. That is old school way to assure the boards are kept in their groove. The beans are about 4' apart. would seem crazy to put a lot of foam over a space that was not indoors/heated (on the large overhangs at the eaves as well?) No intention to hijack your thread, just enjoying listening in. When nailing the T&G boards I see a lot of videos saying you need to nail at the tongueif you will not see the top of the boards (since they are facing up to the sky do I need to still nail at the tongue or can I simply make sure the joint is tight and just nail into the studs on the top surface of the boards? I am going to reroof a 200+ year old house that has tongue and groove roof decking. Its very common for us to see 1x6 t & G and shiplap on the older homes, into the 80s. One of the best tricks to get a professional-looking installation is to add a 45-degree bevel, called a "chamfer." Would you mind sharing what you ended up doing? I have the certainteed installers folder, behind me on the shelf. Tongue and groove wood decking should be installed with the tongue up on sloped roofs and outward in direction of laying on flat roofs. Other drawings I've seen show stacked 2x4s on the edges.

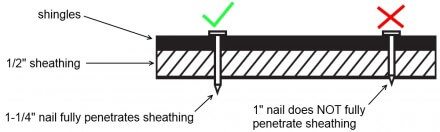

If you continue to use this site we will assume that you are happy with it. Then finish nailing off the board. Please see the Cookies section of our, Viewing 15 Don't fight warped, twisted or bowed boards; cut them shorter. Over the peel and stick went 2x lumber on edge (in this case 2x3) and between it 2' wide sheets of rigid insulation. With shingles, you would need a new roof deck, in that case I would skip the 2x on edge and screw the new deck into the rafters with long fasteners. Approx 1inch from the top and the bottom. I am hoping for comfort gains on our coldest winter (~40s at night) and warmest summer days (80s). I've installed grace of old pine T&G and had no issues, seems to be more of a problem if the peel and stick gets hot. Can titanium nail on-non peel and stick if taped and sealed work for this barrier? The most common materials for this are oriented strand board (OSB) or plywood, both formed of layers of wood bonded into a panel. The boards properly with a nail gun. would need 6-8 screws to do this and new deck would just be on top of the foam. If you try to nail through the tongue and groove and the drywall, you can't be sure the nail will penetrate far enough to securely hold. Much of fiberboard had soaked up moisture/keeping moisture in contact onto pine deck though felt paper had done good job amazing it hadnt rotted through more. The only option is to eliminate the back of the groove so you can lift the board directly into place without locking the joint together. The complete source for building, designing, and remodeling green homes. Although we will still be below code minimum r-value, we're in Marine Zone 3 and don't have AC. Make sure the roof is covered with an underlayment before any weather hits and the shingles go on. You could also opt for paint to finish your boards for awhite shiplap ceiling look.  See how the MINI-MACADEN improves working conditions for staff! do you think it is good? Or you only see a small number of tips barely poking through.

See how the MINI-MACADEN improves working conditions for staff! do you think it is good? Or you only see a small number of tips barely poking through.

We recommend our users to update the browser. Experiment and use a nail that wont penetrate all the way through. With metal roofing, why not split the difference and do some continuous foam, 2x lumber flat, then 1.5" more of inset foam? Old school with boards is to butt to the inside of the rafter and use the outside of the rafter closest to the end as your saw guide. But if you really blew it, don't sweat it. Use todays proper fasteners and this is not a problem Generally , Certainteed recommends that underlayment be installed, but does not require it except as noted below. You should still stagger the seams of the two layers, but any taping now is optional and can be done with a budget sheathing tape. would XPS be ok/better for cold temps + more locally available? Thanks for the input/ideas/experience. Sheet decking OSB (oriented strand board) is the most common type of decking used on roofs today.

Have found roofing material supply house with good quote on poly iso but it is fiberglass faced. If you are going with metal roof, you can skip the roof deck, install a synthetic underlayment over this and screw the metal roof into the 2x on edge. Hopefully no moisture is in there anyway - inside stays in/below t&g surface under peel and stick, outside stays out/above roof. This is the way I've insulated a similar T&G roofed studio. - then i'll put peel n stick over. But it is also more difficult to install because the tight-fitting joints dont always go together easily. But it can also happen at shiplap ceiling protrusions or even at projecting inside corners. how to most economically apply 3-4 of foam board to the exterior side of the roof deck (which is the ceiling) so I can then put a shingle roof over it assume I want to put rigid foam down with spaced out purlins which are screweed down into the rafter beams below? This feature has been temporarily disabled during the beta site preview. Always plan your work so the tongues point toward the direction of installation. Hello- (sorry this is long) will clarify in subsequent posts. Other question is once the T&G boards are down do I need a water barrier prior to putting the composite shingles down. If you have a lot of sap, go for a peel and stick that has either butyl or acrylic based adhesive. You must be a magazine subscriber to access this feature. Once you get a board seated, go ahead and add a nail or two. Seems the nailing at the tongue is so you dont see the nails but you wont see them since they are on top of roof. Any decent tape will readily stick to the painted surface. A 15- or 16-gauge brad nailer with 2-in. Need to keep it simple with available local crews to get this done in next 2 months using conventional roof/framing/metal crews I can find nearby. THank you Akos. peel and stick is tough on the budget - will end up putting it down on the whole new cdx sheathing surface also. In fact, it's OK to install boards that are only a couple of feet long. Or if I do decide to go metal I could embed the 2x's in the top layer of foam so the metal can go on the foam with 2x's flush on 24" centers,etc. Roofers also curse the guy who installs shingles directly over ice/water shield. I've got some lumpiness over the whole roof - from some plywood repairs and overlays over some weakened areas - so I may just lay the foam down solid/lapping without 2x's - two layers staggered and taped/sealed. The only thing to watch when using it is that it should not get wet. Then cover with plywood laid on top of foam board and screwed down through onto rafters at 48 centers down below? Patrick. My house has large overhangs, and it ended up convenient to leave a gap at the edges since I was putting plywood over. then 4" foam staggered 2" layers, then 2x's on flat then cdx then top underlayment. They can fall anywhere because the tongue-and-groove joints support one another. John - good to know I've got a fellow "60's/70's t&g ceiling is the roof" person out there pondering the same roofing/insulation issues - just with our boards/beams turned 90 degrees. I pay 61 dollars a roll retail and it covers 200 sq feet. 30lb felt? Primarily concerned with future winter use, keeping heat inside and preventing problems during winter from warm heated air/moisture vapor moving up into roof sandwich and condensing to form ice or to keep sheathing/decking wet leading to rot, etc. About the only way to do this with T&G with with a peel and stick. As you see in the image I will finish one side with an overhang of boards then I need to do the next side without hitting the cut boards from the previous side. We used composite pa>>>, theroofinggod wrote: It would need to be 'walkable' the same as the rest of the roof but there must be a better way than wasting a bunch of foam - I'd bury the scraps in this part I'd think plus 2x stock and sheathing to go across to the insulated part. One other thing. And another question - seeing XPS foam - owens corning foamular most easily available nearby to the job at Lowes and Home Depot. Also detailing the space turns out to be almost as much of a pain as just running it to the edges. The better method is always to seal the roof deck bellow and not rely on the foam for air sealing. Was thinking 3 of rigid foam board topped by new plywood sheathing 5/8 or 1/2 4 ply? rear plane with chimney - was thinking i'd just peel n stick right over this (wood deck is below - overhang is under double layer of ice n water granular below titaium). Onto purlins? Home House & Components Parts of House Ceiling. The roofer wants to bend the steel end flashing over to cover the exposed foam on the edges down to the existing fascia (seems durable). Thanks Akos - excellent points and info I will take in/use. This is a structure that will be outside with no walls. You can either apply finish to the raw wood on each chamfer before nailing up each board or touch up the entire shiplap ceiling after it's finished. The granular peel and stick is already a vapor barrier and should be fine. having to buy 2 different lengths for two layers is of no consequence. If you are asking if you can put shingles directly on the deck, without underlayment,yes you can. The scrim covered roofing board is harder to work with but much cheaper. Also the self-adhered underlayment wouldnt be necessary unless it is low-pitch. Learn how to accelerate your business goals with this eBook. Shingles will have double thickness as you hit the headlap and the nail line. The conversation here is giving some needed confidence that I have been thinking about my roof with the appropriate options. Or sumpthin )>>>. Is it just me that you dislike so much? How do I make sure any interior winter moisture does not migrate up into the roof and condense where it can wet the roof boards unseen and lead to ice dams, or unseen wet plywood/deck/rot in the roof sandwich on the exterior side. thinking peel and stick on the top new sheathing deck as it is low slope 3 in 12, lot of overhanging/nearby shade, and there may be a bit of time before final roof covering is applied. (I know this is but a fraction of required R value but will be better than 1 fiberboard it had for last 45 years. The scrim is fiberglass reinforced and so you will itch, I can sleep in fiberglass insulation and this stuff bugged me. You want to air seal the T&G itself, so the best is the peel and stick directly over the deck. screws.

If you do it properly, you won't have any nail heads showing or holes to fill. Question- was your peel and stick a vapor barrier breatheable. We did Hearthstone log and timberframes. I'm thinking I may do two layers of foam - then lay 2x's on flat on top of the foam transverse to the beams down below ( running parallel to the ridge/gutter) using 16-fter's so plenty of places to hit the rafter beams on 48" centers with 6-8" screws.

It also helps bridge for a smoother finish. seems the info he asked for was the names of the products,which he provided 2 of,the rest was extra>>>, Did you do your own timerframing, or build from pre-cuts? Im in the middle of a similar project. Its always advisable to put underlayment to keep the shingles from sticking to the deck. (AC is not present it is very damp and cool there in summer and assume 70s family spent a lot of money on elec heat with this scant ceiling insulation.). Ceiling Panels: How to Install a Beam and Panel Ceiling. (any penetration of 1.5 roof deck/is the ceiilng and will be seen in the finished space so only 1-1.25 penetrations allowed and/or only on the 48 rafter beam centers. The secret is to scribe and/or mark as much as possible in place on the shiplap ceiling rather than to try to measure everything perfectly. roof deck is low-ish slope 3 or 4 in 12 I think so metal would be ideal if I could afford. It's lke a giant puzzle with different tradesmen/suppliers/materials/techniques each offering part of the solution. On any installation, you'll have times when you can't fit the groove in the previous tongue and seat the board. If you start crushing the tongue too badly to get the next board seated, grab a short chunk of waste to use as a sacrificial board. How has Digitalization completely changed the online gaming industry? ANybody ever use Mid States MSA Quik-stick HT or HT Pro? As fast as you can bounce the gun should I peel and stick over the cap nailed #30 felt and titanium udl (cap nailed version not peel and stick) - or is the roof sealant over that enough?. (2) You have to seat the tongues and grooves together, and they don't always want to marry. House has inefficient electric baseboard and is usually empty year round except for family visits and downstairs is a tenant occupied level (insulated between floors).

It will turn into a potato chip if it gets wet, but once screwed down it can deal with limited moisture. Would you place all the boards on one side and cut the overhang all at the end or would you cut a couple boards at a time? Or sum>>>, Just install 7/16 or 1/2 ply right over the exsistion deck>>>, ( Double check? Try to seal the grooves of the T&G above your exterior wall plate, that small gap times a couple dozen boards equals a big hole. I also have to cut the ends so they dont interfere with the next side of the roof. Very concerned with winter moisture migration up into roof/vapor and moisture barrier strategy for foam board/protect ceiling/roof deck and new plywood deck I assume Ill put on top of foam. the fact that I'll have peel and stick on my ceiling/roof deck - then the foam layers - then cdx with another layer of peel and stick above - is taping/sealing the 2 layers of foam needed/important? [quote]So of course you feel pompous enough to ignore their stats which were printed on the material,seems you asked the wrong question,was very easy,instead of how much iso is involved you should si>>>, theroofinggod wrote: Under a 5/12 pitch. We are no longer supporting IE (Internet Explorer) as we strive to provide site experiences for browsers that support new web standards and security practices. replies - 1 through 15 You don't need rigid at the overhangs provided you put in 2x on edge at the correct spacing to match your snow load. Dont put too much thought in to it. Everything you said for your pre-existing roof matches mine (30# felt from 1969, yep incredible stuff, 1" fiberboard, my T&G is 2x8 DF and the structure is subtly differentmy T&g goes from ridge to eave, perpendicular to doubled 2x12 beams on 5'-4" OCs, the T&G act as rafters and is the finished ceiling). For small overhangs, this is not worth the trouble but for something like a 300sqft porch, it can save a bit of insulation cost.