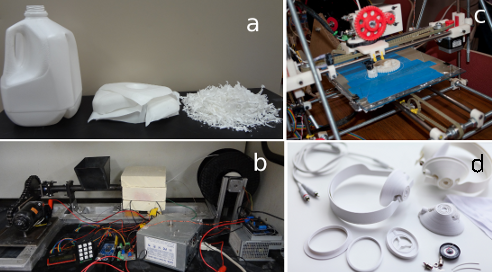

In this paper, research in improving manufacturing sustainability of material extrusion AM is reviewed. The material can be recycled again after its useful life. In general, our company has taken the initiative to cut utility costs and save energy as much as possible by eliminating unused or unnecessary power use. Creating sustainable materials is one of the ways to do so and as AM relies heavily on technology, it can be more flexible, adaptable and promising to grow even greener in the years to come. Although ABS is a non-biodegradable plastic, its chemical properties have been reformulated so that certain bacteria can consume it when it is disposed. M. Azad Emin received his PhD degree in Process Engineering from Karlsruhe Institute of Technology (KIT) in Germany. TimaFlex has been dedicated for years to producing plastics using the most sustainable methods possible. MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. Kerkdennen 62 Environics offers stand alone permeation systems that can be used for single or multiple disposable permeation tubes. Another advantage of this extruder is the amount of material needed for the experiments, which can vary between a few hundred grams per hour to two kilograms per hour.  The finish of the pieces printed with this material has a matte and textured surface due to the wood content, and also retains the characteristic smell of wood. A broader number of applications, circular materials, and technologies were explored by the academic context, concerning the practice-based scenario linked to more consolidated fields. 3D printing opens a new window to integrate waste materials into new objects. Pile of dry soya chunks. Papers are submitted upon individual invitation or recommendation by the scientific editors and undergo peer review After printing it can be post-processed and sanded just like wood. The aim is to provide a snapshot of some of the most exciting work It's the right thing to do. People are looking for a solution to reduce the possible negative impact of their diet on our planet. PLA is also bio-based and biodegradable under industrial composting conditions, making R-PLA a great alternative for achieving a sustainable product. Its most common applications are packaging and housings for electronics. While used in a wide variety of products, plastics have received a substantial amount of negative press relative to the environment. Consequently, there is a demand for a better understanding of those traditional food processes at a mechanistic level. Australian Journal of Mechanical Engineering. There are also PLA-based composites based on PLA with polyester and filled with CF that improve its mechanical properties and temperature resistance (Extrudr Green-TEC Pro). In this latest Way2K interview conducted by the VDMA in the lead-up to the K trade show 2022, Dr. Simon Bard, Product Manager Extrusion at Hans Weber Maschinenfabrik GmbH explains how extrusion technology is helping to advance sustainability. 13: 7269. HIPS for 3D printing is produced in filament form. After that, we are able to adapt the process according to the needs of each specific protein. Of course, it has to be said that many of them are not high-performance and technical materials. Production processes for these plastics have dramatically improved in recent years. These raw materials are very rich in fibers and bioactives, which are very valuable. As a result, we have reduced waste within our production facility to aminimum. The material contains more than 20% recycled tire and has some of the properties inherited from rubber such as good inter-layer adhesion and good abrasion resistance. Because the problem is not whether to use plastic or not. The company strongly supports these efforts and shares any financial gains equally with all associates. Do you want to rethink your products and make them more sustainable? In 2018, more than 50% of the plastic used in our extrusion processes was recycled. We use cookies to enhance your experience. This increasing awareness has been forcing the food industry to undergo major concept revolutions, by changing from traditional foods that we have been consuming for many years to more sustainable food products. Owned and operated by AZoNetwork, 2000-2022, Thermo Fisher Scientific Materials & Structural Analysis, A Laser Disdrometer for All Types of Precipitation OTT Parsivel, Discover the MiniFlash FPA Vision Autosampler, Longer Lasting Sodium-Ion Batteries with Extended Durability, New Research on Radiation-Shielding Concrete, New Eco-Friendly Thermoelectric Material Can Resist Temperatures of 600 C, Producing Sensors with 3D Printed Optical Fibers. Editors Choice articles are based on recommendations by the scientific editors of MDPI journals from around the world. Sustainability 2021, 13, 7269. Recycled materials continue to improve in quality and today nearly 20% (2 million pounds) of the raw materials we extrude incorporate recycled content - either reclaimed from our own manufacturing stream or purchased from outside sources. Future potential research directions are also identified for making AM more sustainable in the future. In this interview, wediscuss the company'snovel technologies and how they could revolutionize how we think about plastics. R-PLA mainly comes from waste filament production as well as printing waste such as supports or failed prints. In order to be human-readable, please install an RSS reader. This bicomposite has a PLA base to which coffee waste by-products (coffe grounds) are added. However, these model systems are often very high in purity, making them very expensive to obtain in large amounts. There are a large number of food by-products, such as apple pomaces from apple juice production, carrot pomaces from carrot juice production, or even potato peel or pulp from potato production. This paper aims to review the main case studies related to new circular economy models for waste valorization through extrusion-based additive manufacturing, circular materials, and new design strategies. Essentially, what this means is, that any leftover materials (plastics, woods, etc.) The filament is composed of TPE (thermoplastic elastomer) combined with rubber from recycled tires. Plastic waste is the problem: it takes a very long time to decompose. However, these raw materials are not really utilized as the addition of these ingredients into food products can adversely affect the texture and mouth-feel of foods. On our work floor, we reuse plastic every day to make new products, for example. Responding to the demand for more sustainable and eco-friendly materials, Bausano, an Italy-based manufacturer of custom extrusion lines, is now offering extrusion lines that are specifically configured for processing plastic waste and natural-fibre composites, the company says. This is the challenge we have as the starting point for our research. This filament has a PLA base that is combined with enviromental harmful algae that have been removed from the environment. Global cosmetics firm LOreal, for example, recently committed to using 100% recycled or bio-based plastics in all of its packaging by 2030. Often the waste used is, like PLA, of biological and biodegradable origin, obtaining a final material that is completely biodegradable and bio-based.

The finish of the pieces printed with this material has a matte and textured surface due to the wood content, and also retains the characteristic smell of wood. A broader number of applications, circular materials, and technologies were explored by the academic context, concerning the practice-based scenario linked to more consolidated fields. 3D printing opens a new window to integrate waste materials into new objects. Pile of dry soya chunks. Papers are submitted upon individual invitation or recommendation by the scientific editors and undergo peer review After printing it can be post-processed and sanded just like wood. The aim is to provide a snapshot of some of the most exciting work It's the right thing to do. People are looking for a solution to reduce the possible negative impact of their diet on our planet. PLA is also bio-based and biodegradable under industrial composting conditions, making R-PLA a great alternative for achieving a sustainable product. Its most common applications are packaging and housings for electronics. While used in a wide variety of products, plastics have received a substantial amount of negative press relative to the environment. Consequently, there is a demand for a better understanding of those traditional food processes at a mechanistic level. Australian Journal of Mechanical Engineering. There are also PLA-based composites based on PLA with polyester and filled with CF that improve its mechanical properties and temperature resistance (Extrudr Green-TEC Pro). In this latest Way2K interview conducted by the VDMA in the lead-up to the K trade show 2022, Dr. Simon Bard, Product Manager Extrusion at Hans Weber Maschinenfabrik GmbH explains how extrusion technology is helping to advance sustainability. 13: 7269. HIPS for 3D printing is produced in filament form. After that, we are able to adapt the process according to the needs of each specific protein. Of course, it has to be said that many of them are not high-performance and technical materials. Production processes for these plastics have dramatically improved in recent years. These raw materials are very rich in fibers and bioactives, which are very valuable. As a result, we have reduced waste within our production facility to aminimum. The material contains more than 20% recycled tire and has some of the properties inherited from rubber such as good inter-layer adhesion and good abrasion resistance. Because the problem is not whether to use plastic or not. The company strongly supports these efforts and shares any financial gains equally with all associates. Do you want to rethink your products and make them more sustainable? In 2018, more than 50% of the plastic used in our extrusion processes was recycled. We use cookies to enhance your experience. This increasing awareness has been forcing the food industry to undergo major concept revolutions, by changing from traditional foods that we have been consuming for many years to more sustainable food products. Owned and operated by AZoNetwork, 2000-2022, Thermo Fisher Scientific Materials & Structural Analysis, A Laser Disdrometer for All Types of Precipitation OTT Parsivel, Discover the MiniFlash FPA Vision Autosampler, Longer Lasting Sodium-Ion Batteries with Extended Durability, New Research on Radiation-Shielding Concrete, New Eco-Friendly Thermoelectric Material Can Resist Temperatures of 600 C, Producing Sensors with 3D Printed Optical Fibers. Editors Choice articles are based on recommendations by the scientific editors of MDPI journals from around the world. Sustainability 2021, 13, 7269. Recycled materials continue to improve in quality and today nearly 20% (2 million pounds) of the raw materials we extrude incorporate recycled content - either reclaimed from our own manufacturing stream or purchased from outside sources. Future potential research directions are also identified for making AM more sustainable in the future. In this interview, wediscuss the company'snovel technologies and how they could revolutionize how we think about plastics. R-PLA mainly comes from waste filament production as well as printing waste such as supports or failed prints. In order to be human-readable, please install an RSS reader. This bicomposite has a PLA base to which coffee waste by-products (coffe grounds) are added. However, these model systems are often very high in purity, making them very expensive to obtain in large amounts. There are a large number of food by-products, such as apple pomaces from apple juice production, carrot pomaces from carrot juice production, or even potato peel or pulp from potato production. This paper aims to review the main case studies related to new circular economy models for waste valorization through extrusion-based additive manufacturing, circular materials, and new design strategies. Essentially, what this means is, that any leftover materials (plastics, woods, etc.) The filament is composed of TPE (thermoplastic elastomer) combined with rubber from recycled tires. Plastic waste is the problem: it takes a very long time to decompose. However, these raw materials are not really utilized as the addition of these ingredients into food products can adversely affect the texture and mouth-feel of foods. On our work floor, we reuse plastic every day to make new products, for example. Responding to the demand for more sustainable and eco-friendly materials, Bausano, an Italy-based manufacturer of custom extrusion lines, is now offering extrusion lines that are specifically configured for processing plastic waste and natural-fibre composites, the company says. This is the challenge we have as the starting point for our research. This filament has a PLA base that is combined with enviromental harmful algae that have been removed from the environment. Global cosmetics firm LOreal, for example, recently committed to using 100% recycled or bio-based plastics in all of its packaging by 2030. Often the waste used is, like PLA, of biological and biodegradable origin, obtaining a final material that is completely biodegradable and bio-based.

What is eco-friendly 3D printing material? This type of 3851 BB Ermelo, The Netherlands. This puts us in a position to turn plastic processing into a truly circular economy. They are recognizing that their choices have a strong impact on the environment and that this is often not a positive one. This poses a risk but also an incredible opportunity all at once. Staying current is easy with Sustainable Plastics' news delivered straight to your inbox, free of charge. Biodegradable ABS retains the properties of ABS high impact resistance, rigidity, high abrasion resistance and chemical resistance. Bio-based and compostable plastics are a rapidly developing field, offering many new possibilities. As a result, countless plastics are being recycled and have become more readily available. This understanding is typically achieved after many years by using a trial and error approach. The Rehau Group will sell its business in Russia to the local management and will withdraw completely from the country. Thermo Fisher Scientific Materials & Structural Analysis. The Role of Extrusion within Sustainable Food Research. Thermo Fisher Scientific Materials & Structural Analysis. It has great versatility and is used in prototypes, accessories, and parts with certain temperature resistance. United Kingdom, Battenfeld-Cincinnati to showcase innovative water management solutions at K 2022, Gneuss MRS extrusion technology makes the PRAE 2022 shortlist, Sustainable flooring quality ensured with Multi-Touch roll stack, Twin screw extruders enable direct up-cycling, Bausano tailors its extrusion lines for natural fibre waste, Teknor Apex lab now offers co-extrusion application testing in Germany, Bausano designs dedicated extrusion lines for biocompounds, KraussMaffei concentrates extrusion technologies under a single roof, Reifenhuser, global spokesperson' for plastics, joins Hall of Fame, Good Natured Products buys Illinois-based sheet extruder Ex-Tech Plastics, Epsotech group launches recycling campaign, realigns organisation. permission provided that the original article is clearly cited. "In a changing world, Sustainable Plastics is a constant: a platform the plastics industry can rely on to deliver the news and knowhow impacting the industry going forward, 11 Ironmonger Lane, EC2V 8EY

R-PET is easy to print and is suitable for printing prototypes, accessories, and large parts. As mentioned above, Plastic Extrusion Technologies has the ability to use 100% reprocessed materials for all the plastic products we make here in Ohio.

Having the ability to use 100% reprocessed materials has helped reduced the size of local landfills. To be even more sustainable, a PLA matrix filled with different waste material is used. The collection is inspired by Mediterranean craftsmanship. It is FDA certified for food contact. Find support for a specific problem in the support section of our website. For Epsotech, a manufacturer of extruded engineered polymer sheet materials, sustainability means, among other things, a focus on recycling, and above all, on recyclability. PA11 is suitable for skin contact and offers great freedom in design as it is produced in powder form. "Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products" Sustainability 13, no. Cited by lists all citing articles based on Crossref citations.Articles with the Crossref icon will open in a new tab. Plans to protect air and water, wilderness and wildlife are in fact plans to protect man. Stewart Udall. This requires a comprehensive understanding of the process and behavior of those sustainable proteins used, which allows us to design tailor-made, meat-like structures. Dr.-Ing. Thanks to the development of new strategies and experiential tools, academic research and practice can be linked to foster new opportunities to implement circular economy models. Teknor Apex has added a new Arvitec co-extrusion line at theirapplication development laboratory in Rothenburg ob der Tauber, Germany. Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. Did you know that with a free Taylor & Francis Online account you can gain access to the following benefits? Recommended articles lists articles that we recommend and is powered by our AI driven recommendation engine. The food industry has started to look for new alternatives and more sustainable ingredients to produce and design food products. Furthermore, extrusion offers huge flexibility with respect to the raw material selection and the wide variety of food products that can be designed by this system. This is one of the main reasons why we decided to work with the company Thermo Fisher Scientific. However, to achieve higher sustainability, the different manufacturers of printing materials now also offer various green material solutions, from plant-based materials, biodegradable materials, recycled materials, materials that include waste from other industries in their composition and materials with new formulations.

Having the ability to use 100% reprocessed materials has helped reduced the size of local landfills. To be even more sustainable, a PLA matrix filled with different waste material is used. The collection is inspired by Mediterranean craftsmanship. It is FDA certified for food contact. Find support for a specific problem in the support section of our website. For Epsotech, a manufacturer of extruded engineered polymer sheet materials, sustainability means, among other things, a focus on recycling, and above all, on recyclability. PA11 is suitable for skin contact and offers great freedom in design as it is produced in powder form. "Design, Materials, and Extrusion-Based Additive Manufacturing in Circular Economy Contexts: From Waste to New Products" Sustainability 13, no. Cited by lists all citing articles based on Crossref citations.Articles with the Crossref icon will open in a new tab. Plans to protect air and water, wilderness and wildlife are in fact plans to protect man. Stewart Udall. This requires a comprehensive understanding of the process and behavior of those sustainable proteins used, which allows us to design tailor-made, meat-like structures. Dr.-Ing. Thanks to the development of new strategies and experiential tools, academic research and practice can be linked to foster new opportunities to implement circular economy models. Teknor Apex has added a new Arvitec co-extrusion line at theirapplication development laboratory in Rothenburg ob der Tauber, Germany. Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. Did you know that with a free Taylor & Francis Online account you can gain access to the following benefits? Recommended articles lists articles that we recommend and is powered by our AI driven recommendation engine. The food industry has started to look for new alternatives and more sustainable ingredients to produce and design food products. Furthermore, extrusion offers huge flexibility with respect to the raw material selection and the wide variety of food products that can be designed by this system. This is one of the main reasons why we decided to work with the company Thermo Fisher Scientific. However, to achieve higher sustainability, the different manufacturers of printing materials now also offer various green material solutions, from plant-based materials, biodegradable materials, recycled materials, materials that include waste from other industries in their composition and materials with new formulations.